It is the responsibility of IMF

Maufacturing Engineering department (S06) to keep the IMF running as smoothly as possible in the production environment and to continuously think about the long term engineering strategy to keep us ahead of the competition. Some of our main responsibilities are :-

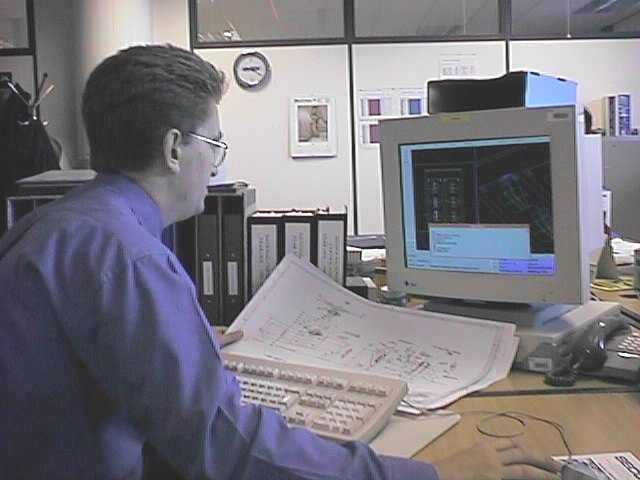

We use CAD/CAM systems called NCL (UNIX based), EdgeCam (PC based) which enable us to create wire frame models of any component then program the toolpath for a specified axis machine, currently we have 3,4 & 5 axis milling centers (Ref cell pages) as well as 4 and 5 axis turning centers.

Once our components have been programmed we have to run them through Vericut which is similar to a virtual machine, simulating how the machine would interpret the toolpath thus enabling us to inspect and measure the component before any material has been cut.

Other roles within the department include process planning which is responsible for all the PEGS & SAP information that production depends on, Smoothing out any production problems and dealing with WQN's etc. We also have a tool design section which is in close interface with the shop floor and the programmers, allowing us to get the best results quickly. The S06 team is made up of people with varying backgrounds in engineering but all with the same goal.

We are also involved quite closely with Research and Technology in their cutter trials, which involves writing programmes that simulate the conditions our cutters are put through in a production environment.

|

|

| Programmer. | Screen shot of Vericut. |

|

|

| Component machined on Hi Cell. | Screen shot of EdgeCam. |

|

|

| Component machined on Automax II. | Screen shot of NCL. |

| If you would like any further information mailto:Manufacturing Engineering Department | |